products - rubber packing sheets

-

Application

for production of gaskets and seals working statically in non-stretched status -

Types of rubber sheets

- SBR - for normal conditions and neutral water solutions,

- NBR - resistant against oils, fuels and fats,

- CR - higher resistance against atmospheric conditions and weak acids,

- EPDM - resistant against oxide, ozone, higher temperature and UV-radiation,

- SBR/AA - resistant against abrasion and tear-off

- NRL - for contact with food

-

Versions

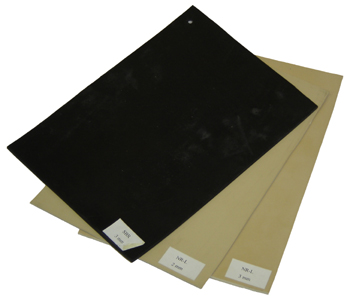

- without textile plies,

- with 1 or 2 textile plies, strengthening the resistance against tear-off

- plain on front and bottom surface,

- with cloth-print on bottom surface

-

Standard dimensions

Thickness, in mm Width, in mm Length, in mm Plies 1 - 1,5 2 2,5 ±0,3 1200 ±30 10000 ±100 1 3 3,5 4 1 or 2 5 6 ±0,5 5000 ±50 8 ±0,8 10 ±1,0 1000 1000 ±30 - ±0,8 1200 5000 ±50 1 or 2 12 ±1,2 1000 ±30 1000 ±30 - ±0,8 1200 5000 ±50 1 or 2 15 ±1,5 20 ±2,0 25 ±2,5 30 ±3,0 1000 ±30 1000 ±30 - 35 40 ±3,5 50 ±4,0

Production of rubber sheets in dimensions and tolerances other than standard ones, is possible upon prior agreement. -

Technical specification

Parameter Type

SBR SBR/CR NBR/SBR EPDM Hardness, °ShA 65±5 65±5 65±5 60±5 Tensile strength, MPa, min. 4 6 5 5 Relative elongation, %, min. 150 200 200 300 Resistance against ageing in air, in 70°C after 70 hours

- Rr,%, max. ±30 - - - - Er, %, max. -50 - - - - H, °ShA, max. ±10 - - - Resistance against ageing in air, in 100°C after 70 hours

- Rr,%, max. - ±30 ±30 ±30 - Er, %, max. - -50 -50 -50 - H, °ShA, max. - ±10 ±10 ±10 Resistance against V-oil, in %, in 100°C after 72 h

30

Density g/cm3 1,45 1,40 1,35 1,25

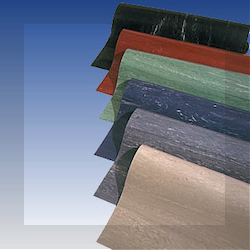

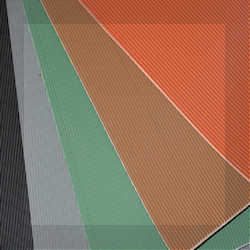

pic 1.

pic 1.

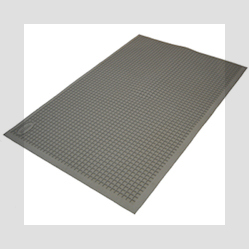

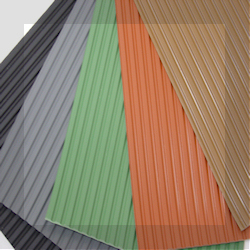

pic 2.

pic 2.

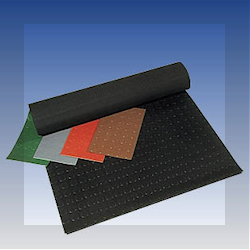

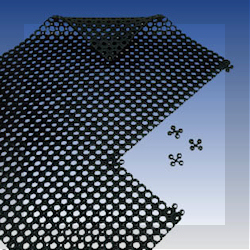

pic 3.

pic 3.

about us

about us

products

products

contact

contact

rubber packing sheets

rubber packing sheets

silicone sheeting

silicone sheeting